The Emerich Energy's AVG (Active Var generator) represents the latest generation technology in the power factor correction field. By eliminating the need for switched capacitors and providing dynamic step-less compensation, the AVG offers high performance in a single Cubicle

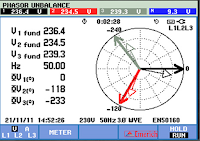

It operates by detecting the load current on a real-time basis through external CT’s and determining the reactive content of the load current. The data is analysed and the AVG’s controller drives the internal IGBT’s by using pulse width modulation signals to make the inverter produce the exact reverse reactive current of the corresponding load reactive content. This is injected to the grid to compensate the reactive content of the load current.By adjusting the output voltage amplitude and phase angle or by directly controlling the AC side current, the AVG can absorb or generate var according to the load reactive power or the grid

AVG OPERATING PRINCIPAL

Load current is detected through external CTs and fed to the internal DSP and CPU where an Instantaneous Reactive Power algorithm separates the active power from the reactive power. A compensating reactive power requirement is dynamically and accurately calculated and sent to the IGBT control where a

PWM signal is generated at a switching frequency of 20kHz. A compensating capacitive reactive power or inductive reactive power is controlled by the manipulation of the DC bus voltage in comparison to the AC line voltage.

Thus a capacitive current or inductive current will flow, creating a reactive power

exchange with the network voltage level

-->Excellent power factor correction performance

Can maintain a PF of 0.99 lagging or unity if required

-->Compensates both inductive and capacitive loads

Corrects lagging and leading power factor (-1 to +1)

Eliminating the weakest link

This new method of Advanced Power Factor Compensation takes away the most vulnerable and weakest link in a traditional APFC system–the switched capacitors. Various environmental conditions (eg.excessive temperature,over-voltage, harmonic distortion) may cause capacitors to rupture and ignite.

The average life span of a switched capacitor is heavily dependent on the ambient temperature in which it is operated – requiring careful selection with respect to permissible operating temperature range. These temperature limits work well in colder climates but may not necessarily work well in all regions. The new generation technology in the Emerich AVG eliminates the operational limitations, safety concerns, space demands and life span issues of capacitor banks.

Operates in all 3 phases

A traditional switched capacitor type PFC system measures one phase and then

provides stepped kVAr compensation to all phases based on the measurements

taken from the one phase being measured. The other two phases all receive the same compensation, irrespective of what the other two phases actually need. The Emerich AVG measures all 3 phases and provides specific dynamic kVAr compensation each phase.

Greater longevity

With traditional capacitor type systems, the physical cabinet space required for

the compensation steps is the same, weather the steps are 6.25kVAr or up to

50kVAr steps. This results in requiring large cabinet space even for small

adjustments. The other disadvantage for having a small step for fine adjustment is that it gets over used (frequently switched). The PFC controller uses an

algorithm that evenly distributes the work load among the available steps except when one or two of those steps are of a smaller capacity. This brings into play the actual usable lifetime of the components used, for example the life of the contactor!

Not affected by resonance

The system is not susceptible to existing harmonics and therefore does not need a blocking reactor and is unaffected by resonance whereas for the traditional

PFC system this is very much a problem.

• Corrects load imbalance

• Can operate at low voltages

• Dynamic step-less compensation

• Profiles the load and operates with a response speed of <15ms

• Dynamic reaction time is less than 50µs

• No possibility of over-compensation or under-compensation

• Only injects the kVAr that is needed in that moment

BENEFITS of Emerich AVG

• Dynamic, Step-less Compensation

+ Adds exactly what is required to meet your Power Factor

+ Targets. No More, No less.

• Results in better Power Factor, for less costs

+ Better results for your critical load

+ Less money spent on power bills

• Better Knowledge of your own network

+ Far more detailed reporting

+ Corrects Power factor changes within 15ms

+ Reacts to changes in less than 50 micro seconds

• Virtually Maintenance Free

+ No capacitors to replace

• Far Safer

+ No capacitors to ignite

LONG LIFE WITH

EXTREME DURABILITY

• 100% solid state with latest generation

IGBTs.

• Electronics free from contaminated air flow

• Long life cooling fans are simple to replace

• Capacitor free. No Need for constantly checking capacitors for

degradation or failure

• Low risk – no swollen or leaking capacitors.

Reduced fire risk.

• No contactors to replace

• Design service life of more than

100,000hrs, without maintenance.

That’s more than 10 years

operation in a plant that operates

24/7. Capacitor based systems

can last as little as three years.

• High power density means

less precious switchboard

room is use

CONCLUSION

Emerich Energy’s AVG is an entirely new approach to power factor correction. The AVG utilizes a high speed three level inverter that reacts to changes in reactive power, exchanging corrective reactive power into the system. Full correction is made in 3/4 of a cycle. This rapid response provides stable accurate real-time power factor correction without the drawbacks of traditional capacitor based systems. The AVG can continuously adjust reactive power dynamically and bidirectionally (leading or lagging). There is no chance of system resonance and even under low voltage conditions AVG will provide full reactive power compensation. The Emerich Energy's AVG is 100% inverter based so there are no AC capacitors to failure.

For Advanced Power Quality products Study & Completely Automated Report:

Connect with Emerich Energy Please write to us info@emerich.in Call: 044-48577667

Please subscribe our blog https://blog.emerich.in/

Follow us LinkedIn https://www.linkedin.com/company/emerichenergy/